Tool Owner

Brian Baker (bbaker@eng.utah.edu)

Reservations Calendar

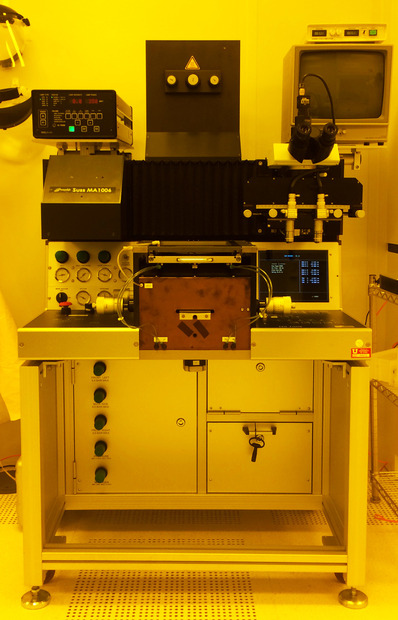

S/N: 06060026

- Top and Bottom Side alignment

- One can expose in all common printing modes using collimated light optics

- Can be used in all major lithography areas:

- M(O)EMS

- Bulk MEMS

- Optoelectronics with more coarse features

- Power devices

- Bumping

- Etc.

- Equipped with a programmable control unit

- Alignment is carried out by means of micro-meter screws

- Z-axis is motorized

- Fitted with a calotte chuck wedge error compensation system

- Top side alignment

- Equipped with a splitfield microscope

- CCD and monitor

- Supports 5″ and 7″ masks

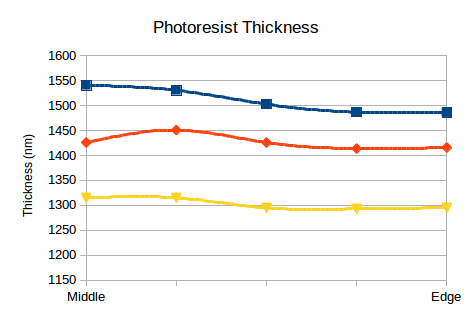

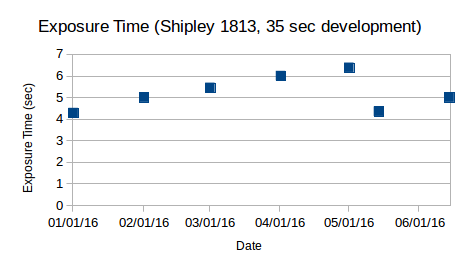

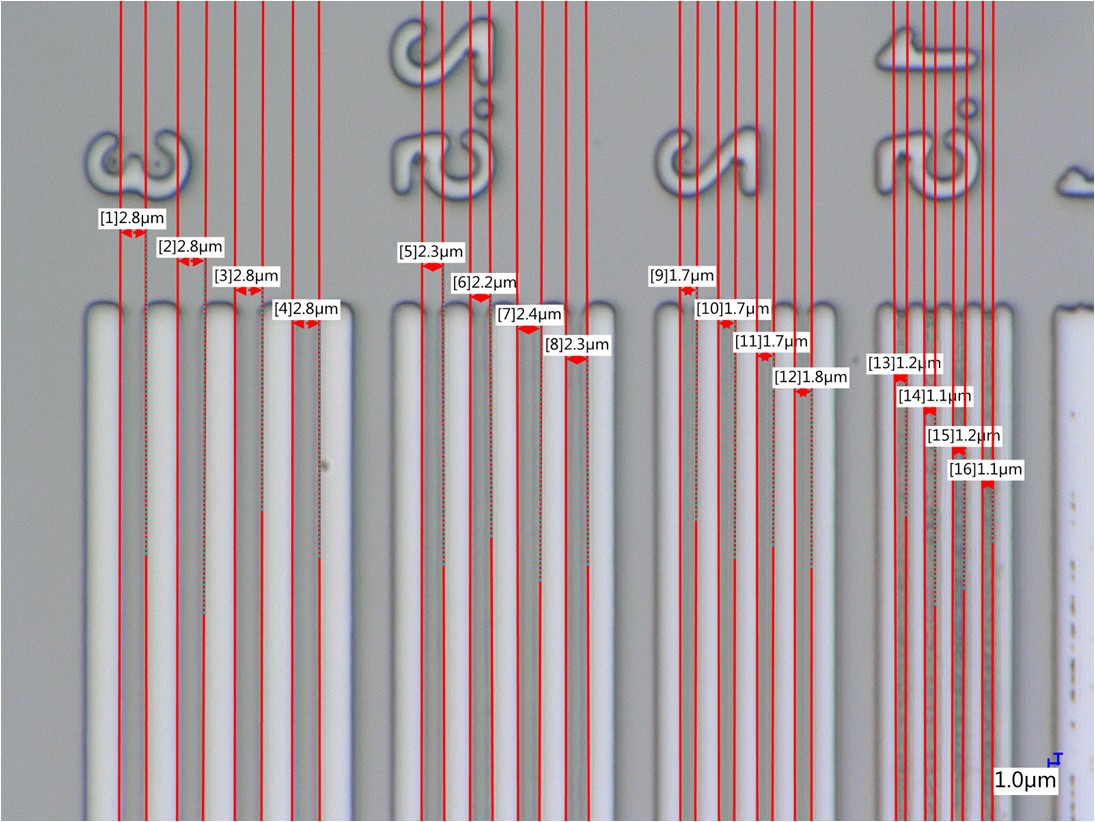

Meausured linewidths (Shipley 1813, 2000 rpm 60 sec spin, 110 C 60 sec hotplate bake, 30 mJ/cm2 exposure dose, AZ 1:1 35 sec)

Minimum measured linewitdth at full photoresist height: 2 um

Download Files

Files

Process Characterization:

Suss Aligner Specs and Brochure

Suss Aligner Characterization July 2015

SOP:

Staff Files

Manual:

Suss Aligner Power Supply Manual

SOP:

Suss MA1006 Aligner SOP Word Format (1)

Run-Data Reports for Suss MA1006

| Processes on Suss MA1006 | ||||

|---|---|---|---|---|

| aborted | ||||

| lab-use | ||||

| service | ||||

| standard-logs | ||||

| runs-without-data | ||||

| Download Combined Report (XLS) |