Tool Owner

Joseph Jacob (joseph.jacob@utah.edu)

Reservations Calendar

S/N 721002

Etching

- Etch Gases: SF6, CF4, O2, Ar, N2, CHF3, C4F8

- Cryo DRIE up to 5 um/min

- 4″ Wafers, 6″ or 8″ wafers with clamp change

Images

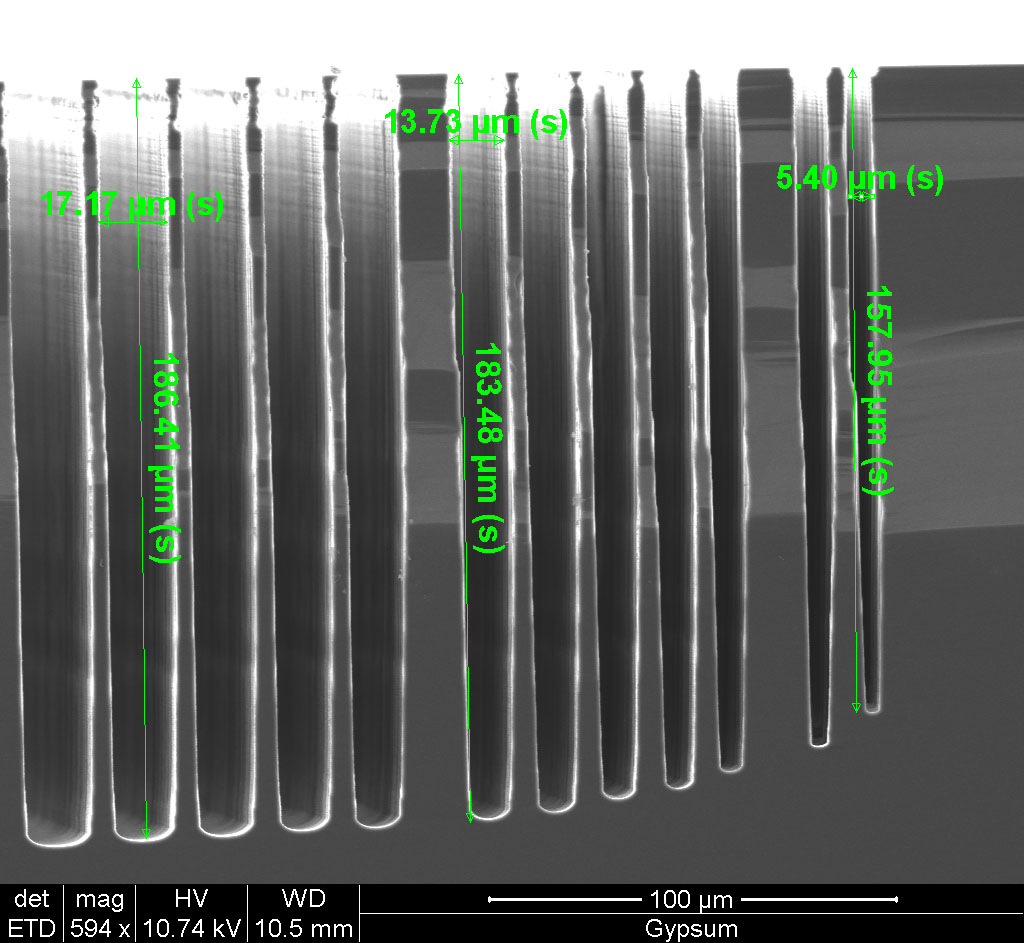

High Aspect Ratio:

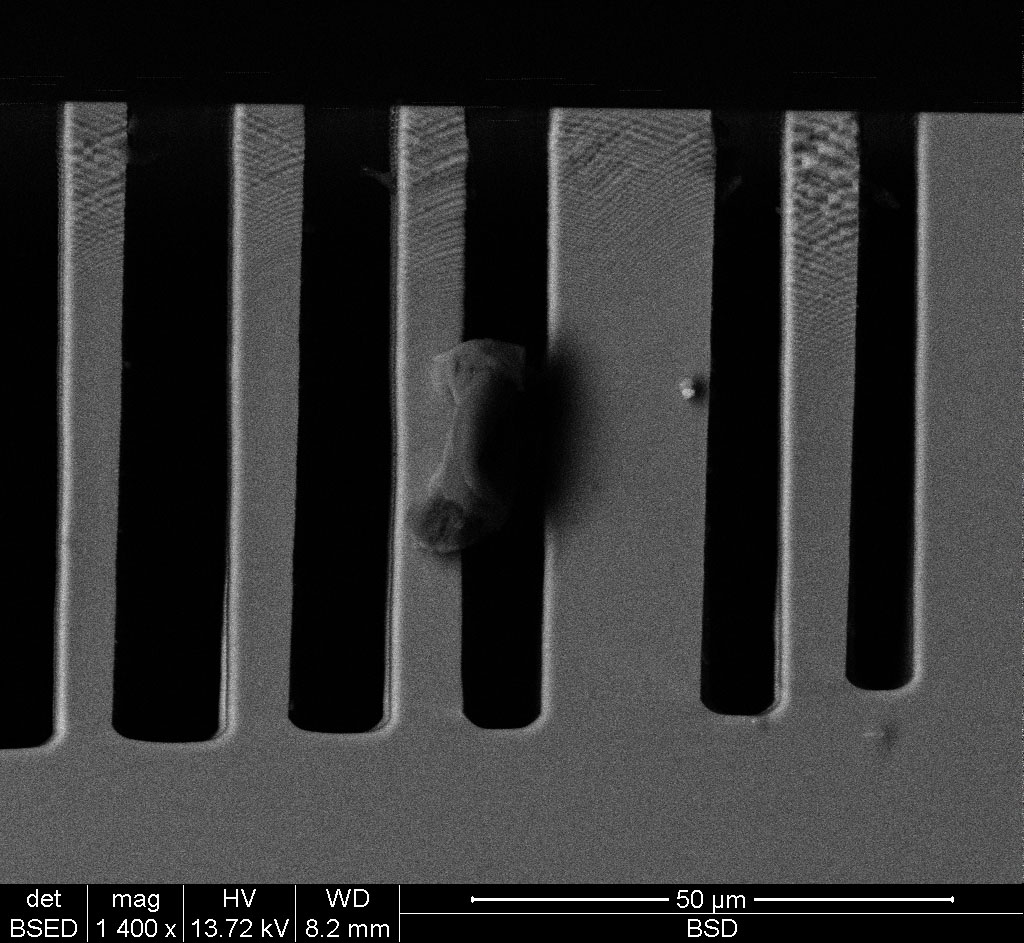

Minimal Undercut:

Process Information

Oxford 100 DRIE SF6/C4F8 Log Sheet

Cross Section Pictures of Results: High Aspect Ratio No Undercut

Run-Data Reports for Oxford 100 ICP

| Processes on Oxford 100 ICP |

|---|

| aborted |

| oxford100 |

| service |

| standard-logs |

| runs-without-data |

Download Combined Report (XLS)

Download Files

Files

Material Etch Rates:

Oxford 100 Material Etch Rates Aug 2011

Process Information:

SOP:

Oxford 100 Cryo DRIE SOP in PDF Format

Oxford 100 ICP 2-Step DRIE SOP in PDF Format

Oxford 100 Processes and Repeatability

Spec Sheets:

Description section from Oxford 100 Manual.pdf

Member Files

Process Information:

Oxford 100 – 9260 Etch Characterization

Staff Files

Manuals:

University-of-Utah-94-721002-System-Manual

SOP:

Oxford 100 Cryo DRIE SOP in Word Format

Oxford 100 ICP 2-Step DRIE SOP in Word Format

Run-Data Reports for Oxford 100 ICP

| Processes on Oxford 100 ICP | |||

|---|---|---|---|

| aborted | |||

| oxford100 | |||

| service | |||

| standard-logs | |||

| runs-without-data | |||

| Download Combined Report (XLS) |